842N – Offset Disc

For those who prefer to use an offset disc, Wishek offers a time-tested design, backed by a long-standing reputation for durability. Not only are Wishek Offset Discs the most reliable on the market, but they’re also the heaviest and lowest maintenance. With approximately 1,000 pounds of weight per foot of implement (1,488 kg/m), the Wishek Offset Disc has the ability to penetrate even the most demanding soil conditions.

Blade, Bearing and Spool Scrapers

The Offset Disc comes standard with specialized scrapers for the blades, bearings and spools. These scrapers help optimize performance of the disc by keeping the gangs free of mud build-up.

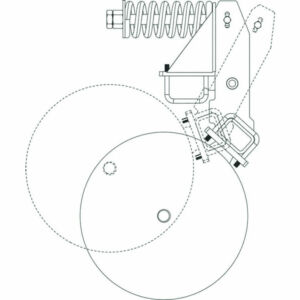

Spring-Cushioned Gangs

When a blade strikes a solid object such as a rock, it travels in an arc of 6 in (152 mm) rearward and 6 in (152 mm) upward for a total of 12 in (305 mm), letting it travel over and avoid damage from impact with that object.

Multiple Blade Options

Choose from 28- to 30-in-diameter (71.1-76.2 cm) smooth or notched blades, according to your needs.

Rear Feathering Blades

To help create an even soil profile, the Offset Discs include feathering blades to remove ridges created by the front gangs.

Manual or Hydraulic Levelling Screws

The disc can be levelled front-to-back manually with levelling screws. A hydraulic option allows this task to be performed from the cab.

Optional Single-Point Depth Control

Single-point depth control allows the operating depth of the entire disc to be adjusted with a single setting. This simple adjustment, done at the front of the machine, is easy, safe and precise.

Rear HITCH

A rear hitch allows finishing tools or other items to be towed behind the disc. Hydraulic and electronic extension packages are available to allow articulation of towed implements.

Heavy Tubular Frame

A 4 x 8 x 3/8 in (10.2 x 20.3 x 1 cm) tubular welded frame not only offers rugged durability, but it also helps provide the weight needed to penetrate tough ground.

FEATURES

Standard Equipment

- 4 x 8 x .375 in (10.2 x 20.3 x 1 cm) Tubular Welded Frame

- 4 x 6 x .25 in (10.2 x 15.2 x 0.6 cm) Tubular Welded Hitch

- Hydraulically Adjustable Running Gear

- IF320/70R15 Tires w/8-Bolt Hubs

- 2,000 lb (907.2 kg) Hitch Jack

- 20,000 lb (9,071.8 kg) Safety Chain

- Hydraulic Hose Holder

- Hazard & Brake Lighting/SMV Kit

Levelling Components

- Manual or Hydraulic Levelling Screws

Implement Hitches

- CAT 4 or 5

Gangs

- 11 in (27.9 cm) Blade Spacing

- 28-30 in (71.1-76.2 cm) Smooth or Notched Blades

- Spring Cushioned

- Angle Adjustment

- 1.938 in (4.9 cm) Shafts

- Tightening Wrenches

- 214 Series Re-Lube Bearings

- Blade, Bearing, & Spool Scrapers

- Rear Feathering Blades

- Optional Bearing Guards

rear Hitch Options

- CAT 0 or Clevis

- Hydraulic & Electronic Extension Packages

Gallery

SPECIFICATIONS

Model 842N 28 x 5/16″ (711 x 8 mm) blades, 30 x 5/16″ (762 x 8 mm) optional, spring cushion gang with 11″ (279 mm) blade spacing

Model Number | Working Width, ft (m) | # of Bearings | # of Blades | Transport width, ft (m) | |||||

|---|---|---|---|---|---|---|---|---|---|

Transport height, ft (m) | Weight per blade, lbs (kg) | Weight per foot, lbs (kg) | Approx. weight, lbs (kg) | Approx. horsepower requirement | |||||

| 842N-10 | 11.5 (3.5) | 6F, 4R | 12F, 13R | 12.58 (3.9) | 7 (2.1) | 441 (200) | 1,003 (455) | 11,029 (5,003) | 135-165 |

| 842N-12 | 12.67 (3.9) | 6F, 4R | 14F, 15R | 14.33 (4.4) | 7 (2.1) | 433 (196) | 991 (450) | 12,550 (5,693) | 155-165 |

| 842N-14 | 14.5 (4.4) | 7F, 6R | 16F, 17R | 15.25 (4.4) | 7 (2.1) | 419 (190) | 954 (433) | 13,830 (6,273) | 175-190 |

| 842N-16 | 16.17 (4.9) | 9F, 8R | 18F, 19R | 17.83 (5.5) | 7 (2.1) | 398 (181) | 911 (413) | 14,720 (6,677) | 195-210 |

| 842N-18 | 17.92 (5.5) | 9F, 8R | 20F, 21R | 19.58 (6) | 7 (2.1) | 372 (169) | 851 (386) | 15,248 (6,916) | 215-235 |

Due to working depth and ground conditions HP requirements will vary.